Sno-Coat™ Enamel is an advanced solvent-based enamel roof cooling paint that that can reduce the internal temperatures of buildings to below ambient. This product also achieves 100% adhesion when preparation and application are done correclty as tested by SABS.

In addition, our advanced enamel roof cooling paint is a world first generation 5 paint coating that has self healing capabilities.

Sno-Coat™ Enamel applied to flat concrete roofs prevents thermal shock to a remarkable degree, which stops cracking and leaking.

Our product works exceptionally well on Zink roofs, preventing rust, thermal shock as well as leaks.

Air temperatures measured inside buildings can drop by up to 15 degrees centigrade, while temperatures of roof sheets, shingles or walls can drop by up to 40 degrees centigrade.

This exceptional roof cooling paint is the very best available and encompasses a modern approach to this technology. Utilizing an advanced metallic, string oxide and also sulphuration complex to achieve it`s extraordinary properties.

Sno-Coat™ Enamel shows excellent resistance to rust show through and also leaves a smooth gloss finish.

Our product has superior adhesion propensity, better opacity, extended coverage, higher cooling capacity and is also chip blister, crack and peel resistant.

You do not need to use a primer with Sno-Coat™ Enamel.

6 light colours to choose from ( white works best )

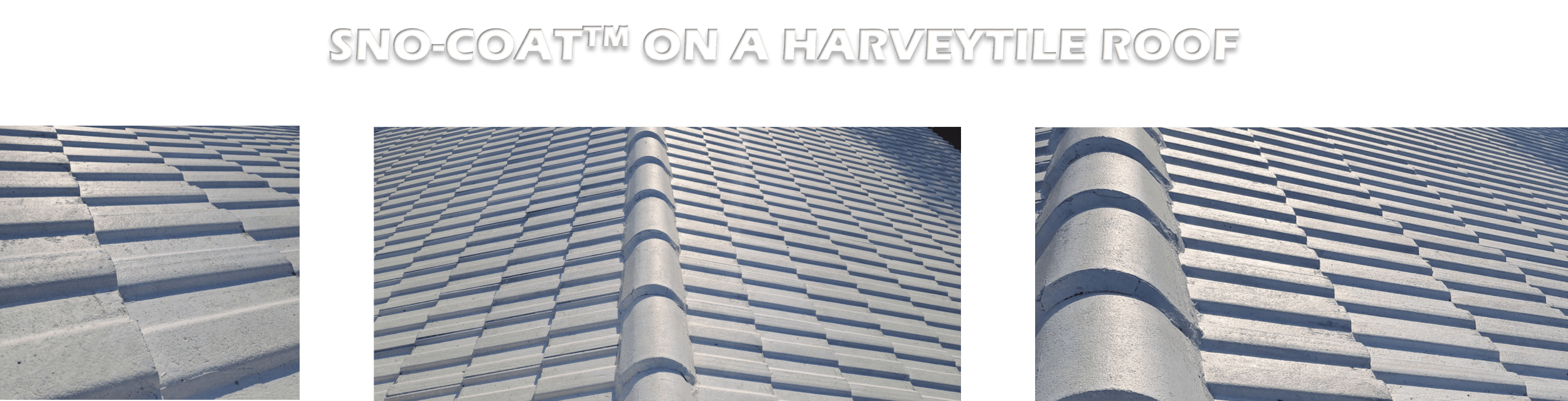

Sno-Coat™ Enamel is suitable for use on steel, IBR, Harveytile, cement fibre, asbestos, concrete and shingle roofs.

Some examples of ideal uses for Sno-Coat™ Enamel are shopping centres, hotels, churches, farming warehouses, homes, factories, schools, office buildings and hospitals.

We recommend the use of Sno-Coat™ Enamel on any building that is in need of cooling and thermal shock protection.

Experience up to 25% decrease in roof temperature amounting to huge energy savings.

Surface preparation

Ensure that the surface is free of loose paint, dirt, grease as well as grime.

In addition, the substrate must be dry prior to applying Sno-Coat™ Enamel.

Priming

You do no need to use a primer with this product.

Application

Apply Sno-Coat™ Enamel by brush, roller as well as spray.

( minimum of 2 coats recommended )

Coverage

8 square metres per litre depending on the substrate as well as method of application.

Cleaning

Clean equipment with mineral turpentine or any other high quality solvent after painting.

Then rinse the solvent off the equipment with water.

ADVANCED ENAMEL ROOF COOLING PAINT

Sno-Coat™ Enamel is a wet in the can paint on coating with thermal insulating, rust preventing and other properties.

![]()

Can reduce air conditioning installation and running costs by up to 25%

Reduces thermal shock by up to 50%

Increases rust onset and degradation time by up to 300%

Prolongs substrate life by up to 300%

Increases live carry capacity by at least 25% (Chicken house)

Decreases heat stress mortality by more than 90% (Chicken house)

Summer inside temperatures decrease by up to 30%

Roof substrate temperatures drop by up to 50%

Excellent waterproofing properties.

Aesthetically pleasing.

HOW Sno-Coat™ Enamel WORKS

![]()

Table 1: Solar Reflectance Index (SRI) for Typical Roofing Materials

Example SRI Values for Generic Roofing | Solar Reflectance | Infrared Emittance | Temperature Rise | Solar Reflectance Index (SRI) |

| Grey EPDM | 0.23 | 0.87 | 68F | 21 |

| Grey Asphalt Shingle | 0.22 | 0.91 | 67F | 22 |

| Unpainted Cement tile | 0.25 | 0.9 | 65F | 25 |

White Granular Surface Bitumen | 0.26 | 0.92 | 63F | 28 |

| Red Clay Tile | 0.33 | 0.9 | 58F | 36 |

| Light Gravel on Built-Up Roof | 0.34 | 0.9 | 57F | 37 |

| Aluminum | 0.61 | 0.25 | 48F | 56 |

| White-Coated Gravel on built-up roof | 0.65 | 0.9 | 28F | 79 |

|

|

|

| |

| White EPDM | 0.69 | 0.87 | 25F | 84 |

| White Cement Tile | 0.73 | 0.9 | 21F | 90 |

| Sno-Coat – 1 Coat | 0.8 | 0.91 | 14F | 100 |

|

|

|

| |

| Sno-Coat 2 Coats | 0.85 | 0.91 | 9F | 107 |

Source: LBNL Cool Roofing Material Database. These value are for reference only and are not for use as substitutes for actual manufacturer data.

Our advanced enamel roof cooling paint can drop the interior temperature of a building to below ambient. This exceptional thermal coating is the very best available, and also encompasses a modern approach to this technology.

Cosmo-Dec Everlasting Coatings originated in 1991, with a single product – Therma-Masta™.

Knowledge gained from manufacturing this complex and unique product allowed us to formulate new and innovative products such as Fire-Guard™, Aqua-Mite™, Aqua-Therm™, Clean-Air, etc. for specialty applications.

To-day, 3 decades on we manufacture more than 80 different types of construction chemicals out of our factory in Pretoria, Gauteng.