Sno-Coat™ is an advanced roof cooling paint ( Infrared thermal radiation reflector ) that can reduce internal temperatures to below ambient.

THIS PRODUCT HAS THE FOLLOWING PROPERTIES

PRODUCT INFORMATION

Our advanced roof cooling paint has superior adhesion, extended coverage as well as a higher cooling capacity.

In addition, It is also chip, crack, blister and peel resistant.

Sno-Coat™ is waterproof, unaffected by ultra violet light, flexible as well as impact resistant.

Our advanced roof cooling paint can be applied to ANY roof type including galvanized iron and also glass, with a drying time of 30 minutes in warm, dry weather.

Use Sno-Coat™ to cool your home, office, farm or factory and start saving on electricity as well as air conditioning running costs.

Sno-Coat™ prevents fungi, moss as well as algae growth on the roof.

This exceptional thermal coating is the very best available, and also encompasses a modern approach to this technology.

COLOURS

Sno-Coat™ is available in snow white as well as 5 light pastel shades.

ADVANCED WATER-BASED ROOF COOLING PAINT

SUITABLE SURFACES

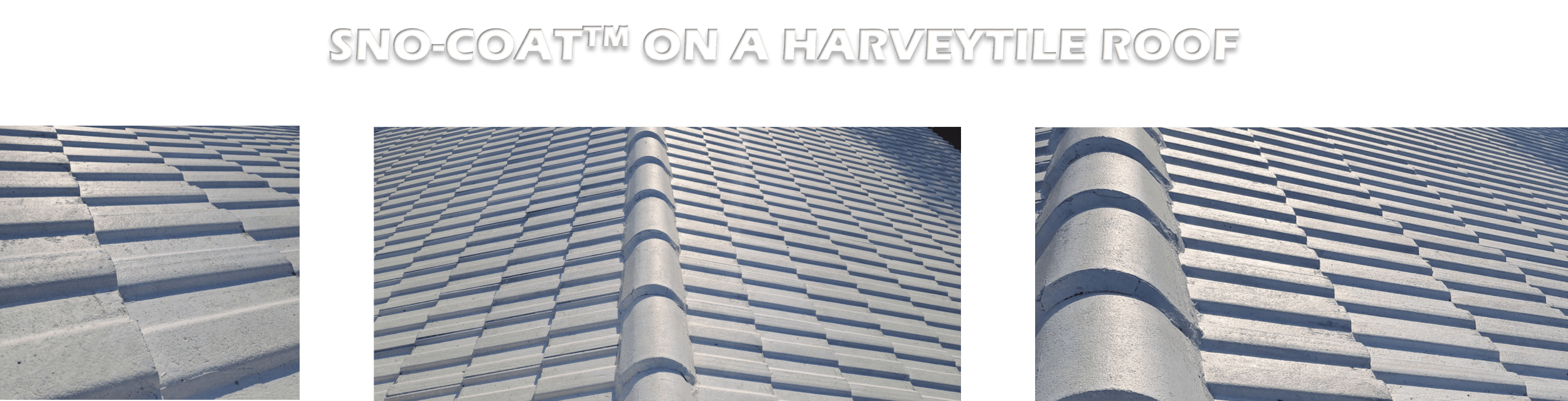

Sno-Coat™ is suitable for use on steel, IBR, Harvey tile, cement fibre, asbestos, concrete as well as shingle roofs.

You can also use Sno-Coat™ on walls and other surface types including timber.

Some examples of ideal uses for Sno-Coat™ are shopping centres, hotels, churches, farming warehouses, homes, factories, schools, office buildings as well as hospitals.

APPLICATION

Surface preparation

Ensure that the surface is free of loose paint, dirt, grease as well as grime.

In addition, the substrate must be dry prior to applying Sno-Coat™.

Application

Apply by brush roller as well as spray.

As a rule, a minimum of 2 coats are required in order to achieve the desired cooling.

Paint brushes, rollers, equipment and also spray machines can be washed with water after use.

Coverage

4 to 5 square metres per litre depending on the substrate as well as method of application.

![]()

The best surface primer to use with Sno-Coat™ is Dead-End™, Dead-End™ creates a water tight vapor barrier and also improves adhesion.

ADVANTAGES

Thermal Insulator (Cools) as well as Acoustic insulator.

Seals asbestos fibre roofs (Government regulations) and also saves electricity.

Waterproofer as well as Rust Protector/Inhibitor.

Water-Based, Non Toxic, Long Lasting, easy to apply as well as Inexpensive.

Addresses climate crisis issues and also Combats climate change.

Can reduce air conditioning installation as well as running costs by up to 25%

Reduces rust onset and also degradation time by up to 300%

Prolongs substrate life by up to 300% and also reduces thermal shock by up to 50%

Decreases summer indoor temperatures by up to 30% and also drops roof substrate temperatures by up to 50%

Increases live carry capacity by at least 25% and also decreases heat stress mortality mortality by more than 90% (Chicken house)

Sno-Coat™ works on all roof types and is also very easy to apply!!

ADVANCED WATER-BASED ROOF COOLING PAINT

You can also contact us by filling out the ‘Need our help?’ form on our website.